A flame-retardant material and its preparation method and application

【Field of Technology】

- Synthetic chemistry

- Polymer chemistry

- Photo chemistry

- Additive manufacturing (3D-Printing)

- Thin layer Coating

- Flame retardancy

【Technical Keywords】

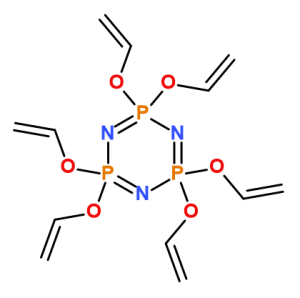

Cyclophosphazenes, hybrid materials, flame-retardants, photo switchable, 3D printing

【Feature of Technology】

- Monomer is liquid at room temperature

- Very simple to make

- High P and N content

- Six vinyloxy groups amenable to radical polymerization

- Polymers form as densely crosslinked species

- Easy to form copolymers

- Easily applied on most surfaces by simple coating techniques

【Market Prospect】

a. All polymeric materials and fabrics

b. Ceramic materials

c. Building materials

d. Electronics and safety materials

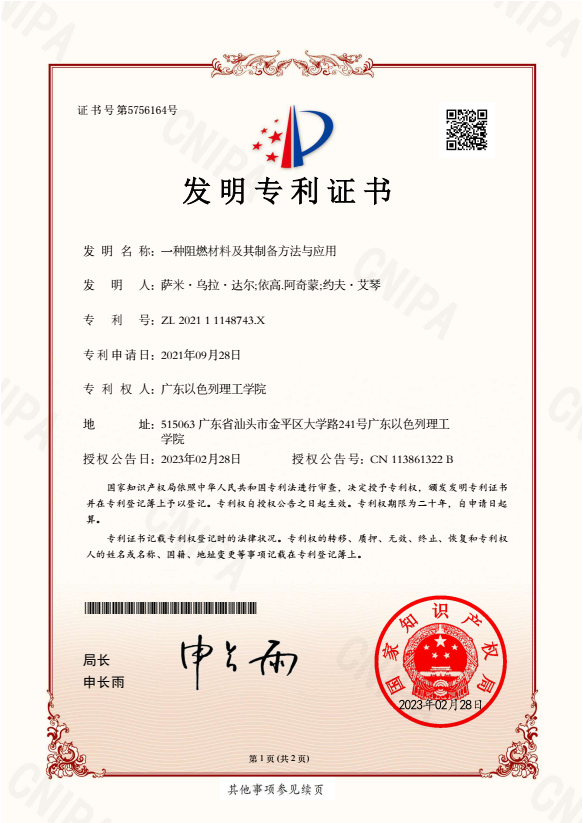

【With patent or not】

A flame-retardant material and its preparation method and application

一种阻燃材料及其制备方法与应用 (专利号:ZL 2021 1 1148743.X).

【With Paper or not】

We are in the process of writing a high impact factor publication on our technology as soon as the patent is granted. Patent is under substantial examination at the moment.

Industry-Leading Level:

Our technology is much cost effective, time effective, facile and highly advanced at world leading level in all its applications.

【Technology Maturity Level】

TRL8: The whole system is completed and validated through tests and demonstrations.

The material and technology is validated under expected conditions. In general, this stage represents the system moving on to the final completion phase.

【Performance Index】

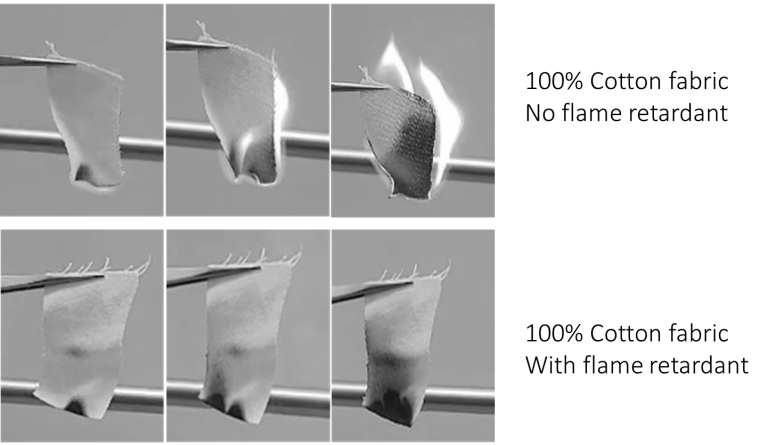

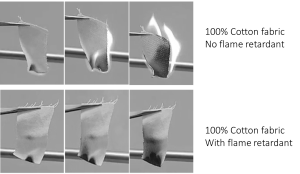

The major tests, we perform for checking the flame retardancy capacity of any material is limiting oxygen index (LOI), vertical flame retardancy tests (VFT )and cone calorimetric (CC) tests for Heat release and transfer (HRT) check. All the tests have indicated the best possible results to date.

【Field of Application】

Our material can be applied as photo switchable flame-retardant material in 3D form on all types of polymeric, fabrics, ceramic, buildings, electronic and safety setups.

【Partner Profile】

- Fabric industries

- Paint and dyes industries

- Auto mobiles and heavy-duty vehicle industries

- Electronics and semiconductor industries

- Building industries

- Ceramic industries

- House hold and kitchen manufacturing industries

- (BASF, SOLVAY etc)

【Technology valuation (optional)】

I cannot say with conviction but if we are successful in commercializing this technology, it will worth in billions of dollars.

【Expert Introduction】

1. Dr. Sami Ullah Dar

Teaching & Research Fellow

Dr. Sami Ullah Dar did his Bachelor`s (hons) degree in chemistry from Government College University, Lahore, Pakistan in 2009. He went on to do Master`s degree as Research Chemist specializing in medicinal and synthetic organic chemistry from University of Eastern Finland (Joensuu and Kuopio campuses) in 2012. He joined high school teaching afterwards in Pakistan and taught Chemistry to the students of the age from 14 to 18. Later, Dr. Dar joined department of materials science and engineering in Beijing University of Chemical Technology in 2015 and obtained his doctorate in June 2018 specializing in polyphosphazenes materials chemistry. His areas of research include but are not limited to Analytical chemistry, Organic chemistry, Materials chemistry and Chemistry education. He joined chemistry department of GTIIT in December, 2018. Dr. Dar has published his research results in reputable journals of RSC, Elsvier and Frontiers.

In addition, Dr. Dar is currently acting as a Research Fellow in Chemistry Working on the Synthesis of Bio-degradable plastic Polymers and 3D printable polymers under the joint supervision of Prof. Yigal Achmon (GTIIT) and prof. Yoav Eichen (Technion).

2. Prof. Yoav Eichen

Schulich faculty of chemistry, Technion-Israel Institute of Technology, Haifa Israel.

3. Prof. Yigal ACHMON

Biotechnology and Food Engineering, Guangdong Technion-Israel Institute of Technology, Shantou, China

If you are interested in this technology, feel free to contact GTEC: gtec@gtiit.edu.cn